Foiling for Print

If you’re looking to add some metallic, shiny logos and text to your printed pillow boxes, foil stamping is a beautiful and subtle way to enhance the design. At Printed Pillow Packs, you have the option to add foiling through either digital foiling or hot foil stamping, but what sets these methods apart? Here’s a quick guide to help you decide which one is best for your pillow box printing needs.

Digital Foiling

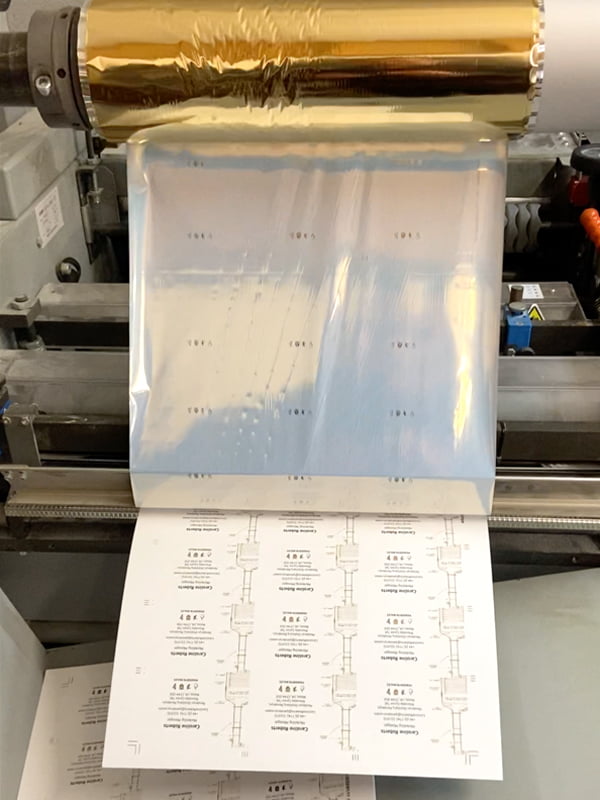

If you’re considering a more affordable and quicker option, then digital foiling might be the better choice. This technique only needs a digital artwork file that directs the digital foil machine on where to apply the foil onto the paper. It’s a great option for those who are looking for a faster turnaround time and have a smaller budget.

The pros of digital foiling:

Digital foiling is a cost-effective option for printing small quantities of items. It is an economical choice compared to hot foil stamping, which requires a die block and is more suitable for larger print runs. Additionally, digital foiling has faster production times, making it ideal for rush jobs or last-minute printing needs.

The cons of digital foiling:

Another downside to digital foiling is that it may not have the same durability as hot foil stamping. Since the foil is applied to the surface of the print, it may be more susceptible to scratching or peeling off over time. This is especially true if the printed product is exposed to rough handling or frequent use. Therefore, if you require a high level of durability, hot foil stamping may be a better option.

Digital foiling at Better Printing

Hot foil stamping

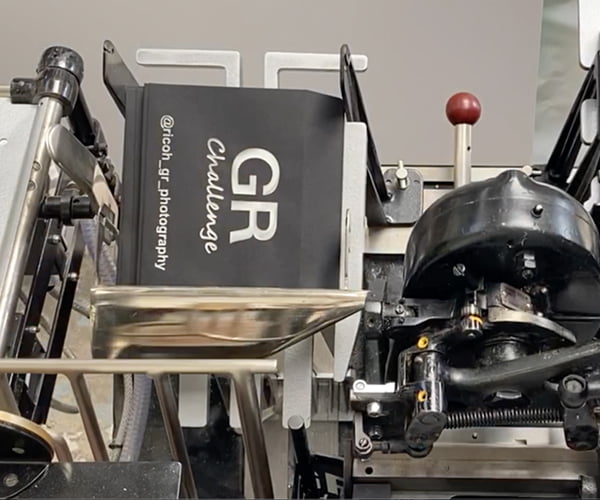

Hot foil stamping is a premium option for high-quality foiling on your printed pillow boxes. This method involves using a press loaded with a custom-made die, the paper product to be foil-stamped, and a sheet of foil in between. The die plate is heated up and then pressed onto the foil and printed item. Only the areas of the foil that come into contact with the die are transferred onto the paper, resulting in a beautiful, debossed effect. However, hot foil stamping comes with additional costs, such as the assembly of your foiling die, which will vary depending on the size of the area you want to foil on your pillow boxes. This extra cost may not be an issue if you’re looking to order a large quantity of foil-stamped items.

Custom brass die block for foiling

Coloured hot stamping foils

The pros of hot foil stamping:

Hot foil stamping offers more professional results compared to digital foiling, especially for rendering small and/or thin text. The stamping process slightly de-bosses the foiled elements, which gives them a subtly-enhanced shimmer under the light. If you’re looking to print a large batch of pillow boxes, hot foil stamping is a more economical option compared to digital foiling, which is more cost-effective for shorter print runs.

The cons of hot foil stamping:

If you’re looking for high-quality foil printing, Printed Pillow Packs offers both digital foiling and hot foil stamping services in-house at our Southampton print factory. While hot foil stamping provides more professional and elegant results, it requires additional time and cost to set up the die block, making it a better option for longer print runs.

Hot foil stamping machine

If you have any additional questions about any type of foiling then call us on 023 8087 8037 or email us.